A Survey of Artificial Intelligence in Oil & Gas

By Bri Conn

Cover image can be found here.

Artificial intelligence (AI) is revolutionizing a wide variety of industries, increasing efficiency, and helping to make previously impossible tasks viable.When you think of industries that are hiring mass amounts of software engineers and data scientists, mining and fossil fuel extraction may not come to mind; however, these industries are finding innovative ways to use these new technologies and adapt to new challenges [1].

Oil & gas extraction has historically been a labor intensive process; however, new technology including sensors, algorithms, and digital communication abilities are being deployed to reduce risks, increase accuracy, and lower expenses [1]. The industry is facing multiple challenges including declining low-cost resource availability, increased difficulty recruiting employees, as well as a growing concern for sustainability from the general public and shareholders alike [2]. These are all key areas that companies are hoping investments in AI will help to solve.

Some of the key tools being implemented include specialized sensors that are used to collect data, which is then processed by software programs. Much of this new technology is aimed at making better use of data to identify patterns. The software is then able to predict the system’s behaviour to an extent, which can help staff to better understand the system and operate it more efficiently. This can help to reduce the costs of discovering and mapping new reserves of oil or gas through the use of AI applied to seismic information, speeding up the project exploration phase by over 100 times [3]. Another use case for AI in the fossil fuel industry is improving safety. Let’s consider one example: British Petroleum’s (BP) collaboration with Kelvin AI at a Wyoming natural gas site [2].

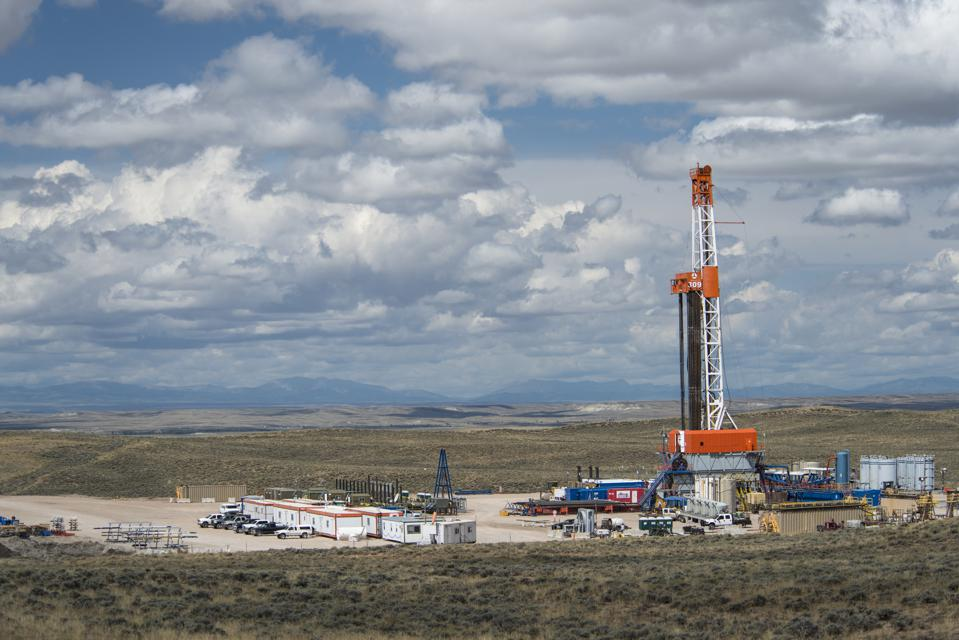

The Wamsutter field, located in southern Wyoming, is home to over 2000 natural gas wells, which extract the gas from extremely tight rock formations [4]. In 2018, they hired Kelvin AI to provide a system of hundreds of sensors, including accelerometers and methane detecting cameras, which were set up on 180 wells. These sensors were tasked with gathering and transmitting data to Kelvin’s supercomputers, which run AI based programs for production optimization. The program worked by controlling certain well actions and analyzing their impacts to learn about how the system functions. Next, the software took control of the wells’ operations with the goal of optimizing production. Initial evaluations suggested that methane releases from the outfitted wells decreased by 74% with this technology implemented, alongside a 20% increase in production and 22% decrease in operational costs [4]. Beyond these remarkable improvements to its oilfield operation, the Wamsutter trial has shown BP that sites using AI can require a lot less staff. They have found they require 43% fewer workers to operate the sensor-equipped wells as automation has decreased the need for manual intervention and increased safety on-site, with less risk of injury [5]. Another major oil company, Royal Dutch Shell, has tested out automation and AI systems at off-shore drilling platforms in the North Sea, and has seen a 40% increase in operational output alongside a 60% decrease in costs [5].

Figure 1: BP oil well in Wamsutter, Wyoming. Original image can be found here.

Another advantage that AI offers the oil and gas industry is help with lowering greenhouse gas emissions. Historically, engineers have attempted to quantify emissions by using their knowledge of physical processes and mathematical modelling to make an educated guess at what’s actually happening out in the field [2]. Emissions are difficult to track due to the dynamic nature of Earth’s atmosphere and the complex physical layout of fossil fuel infrastructure. Many routine operations and maintenance activities release emissions (i.e. reducing gas pressure in a pipeline when performing repairs) and these expected emissions are not what companies are most interested in tracking [6]. Some companies consider focusing on monitoring for unexpected high emissions events - accidents, leaks - to be the real ‘quick win’ strategy for reducing their total emissions. By identifying point source leaks more quickly, infrastructure can be repaired and they can reduce the impacts of accidents. Real-time emissions tracking is an emerging technology, and companies are attacking the problem from different angles. There are start-up companies working on tracking emissions using sensors on vehicles, low flying planes, and even satellites orbiting the Earth all aiming to detect unexpected emissions as early as possible [6].

GHGSat is a Montreal based company that provides emissions monitoring services to various clients in the oil and gas industry using their constellation of small, emissions detecting satellites [7]. The company has launched multiple iterations of satellites that are tasked with identifying and quantifying methane emissions from upstream and midstream oil and gas facilities. GHGSat’s latest satellite - Iris, launched in September 2020 - orbits the Earth at approximately 550 km and its sensors allow for a spatial resolution of 25 m, which gives Iris the ability to identify individual oil wells and pipelines [7].

Figure 2: Iris, GHGSat’s latest emissions tracking satellite was launched in September 2020. Original image can be found here.

Figure 3 shows data collected from Iris’s first test in October 2020, when GHGSat monitored a controlled methane release from a client located in Alberta. Iris’s readings were compared to data taken on the ground and from a low flying aircraft to ensure that the satellite was taking accurate readings. In the coming years, GHGSat plans to launch 10 more emissions tracking satellites [7]. The capabilities of technology like GHGSat will allow for continuous monitoring of all pipelines and extraction facilities. This will let companies identify and stop leaks faster than current methods. This real-time monitoring will help to reduce unnecessary emissions, and when paired with AI technologies to analyze historical data, help reduce emissions from the oil and gas industry.

Figure 3: Methane Detection and Measurement from Alberta. Original image can be found here.

We can only expect AI to become more prevalent in oil fields and offshore drilling platforms [5]. The challenges of sustainability, worker safety, and resource availability will not be going away anytime soon. New AI tools will become essential to retain high profit margins in the oil and gas industry, as new reserves become increasingly difficult to access [2]. New algorithms will need to be developed to predict equipment failure, automate dangerous work, analyze reserves, and identify sources of emissions. Although it may not be Silicon Valley, thousands of bright software engineers will be needed to help spearhead these technologies in order to meet the challenges of the 21st century.

References

[1] M. Guillen, “Five ways technology will change the mining, oil and gas industries,” World Economic Forum, May 2017. [Online]. Available: https://www.weforum.org/agenda/2017/05/five-ways-in-which-technology-will-change-the-extractive-industries/. [Accessed: April 12, 2021].

[2] GlobalData, “Artificial Intelligence (AI) in Oil & Gas – Thematic Research,” GlobalData

March 2021. [Online]. Available: https://store.globaldata.com/report/gdog-tr-s046--artificial-intelligence-ai-in-oil-and-gas-thematic-research/. [Accessed: April 18, 2021].

[3] D. Koroteevab, Z. Tekica, “Artificial intelligence in oil and gas upstream: Trends, challenges, and scenarios for the future,” Energy and AI, Volume 3, March 2021. [Online]. Available: https://www.sciencedirect.com/science/article/pii/S2666546820300410. [Accessed: April 27, 2021].

[4] C. Helman, “BP's New Oilfield Roughneck Is An Algorithm,” Forbes Energy, May 8, 2018. [Online]. Available: https://www.forbes.com/sites/christopherhelman/2018/05/08/how-silicon-valley-is-helping-bp-bring-a-i-to-the-oil-patch/?sh=5ce24a7230a8. [Accessed: April 27, 2021].

[5] C. Helman, “How Algorithms Are Taking Over Big Oil,” Forbes Energy, January 14, 2019. [Online]. Available: https://www.forbes.com/sites/christopherhelman/2019/01/14/how-algorithms-are-taking-over-big-oil/?sh=6e253fc8e2fa. [Accessed: April 27, 2021].

[6] N. Downey, A. Milas, “Keeping an Eye on Oil & Gas,” GHGcast, November 27, 2020. [Podcast]. Available: https://www.ghgsat.com/podcast/.

[7] GHGSat, “Smallest Methane Emission Ever Detected By Satellite,” GHGSat, October 8, 2020. [Online]. Available: https://www.ghgsat.com/smallest-methane-emission-ever-detected-by-satellite/. [Accessed: April 12, 2021].